Take a visual journey with the Acer team as we IGNITE BRAND PRIDE for one client. We’ll walk through the development, fabrication and installation of a 20’x40′ exhibit, from first rough sketches, to the moment the show opens, and even a later exhibit upgrade.

The Client: ROCKWOOL®

The ROCKWOOL Group is the world’s leading manufacturer of stone wool insulation. Their brand is thoroughly modern yet inherently organic; their core products are derived from ancient stone.

ROCKWOOL offers a full range of high performing and sustainable insulation products for the construction industry, which helps address many of the big issues of modern living.

Project Design:

The project kicks off with a collaboration and discovery session with the client. The Acer account and creative teams delve into the brand and messaging as they start to formulate an exhibit strategy that will translate the brand promise into structure.

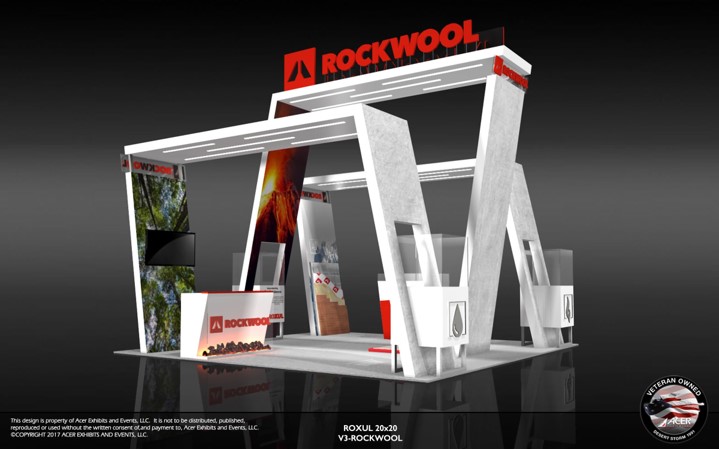

With builders composing the target market, the ROCKWOOL exhibit required a strong architectural component. Acer designers quickly came up with a rough concept featuring three cantilevered arch towers stretching over and across the space.

To really create a suitable branded environment, a review of functional and spatial requirements is completed. The team then explores the exhibit experience from the vantage point of the show attendee.

Through each step, we consider what we want each attendee to:

- THINK: What are the facts about the brand? (Usually this is the client’s most basic positioning statement.)

- FEEL: What is the emotional response we want to evoke as a connection to the brand?

- DO: How can we create an engagement that goes beyond simple observation to strengthen and deepen the brand connection?

- KEEP: What kind of physical artifact can we provide to recall interaction with the brand?

- SHARE: How can we encourage sharing of the experience on social networks?

This is where the Acer design team really shines. As they consider the attendee experience, they begin to envision the structure required to support it. Often, on-the-fly sketches are created during this session, such as those shown here.

Rendering:

The design team now takes the infant exhibit to the next level. Incorporating their preliminary ideas, inspiration boards, competitive research and brand knowledge, they begin to create a space that reflects the brand and delivers on goals for the show.

The first renderings are usually conceptual, employing generic graphic placeholders and roughed-in fixtures to give a starting impression of the design. Most projects start with at least two completely different concepts, with the client choosing which one they prefer to make a reality.

Once a design concept is selected, iterations and tweaks begin, with refinements continuing as the final vision becomes clear to all.

The final rendering will look very close to the actual show floor exhibit, even before a thing is built.

Locking In:

As the design finalizes, the client approves selections for material choices, surface finishes, branding options and structural layout. These are graphically represented in a control rendering to ensure alignment of all Acer internal teams and the client.

Once these selections are finalized, the purchasing team gets to work ensuring that all components arrive at the Acer production floor on time and on budget.

It’s Getting Real!

At this point, the translation from idea to reality begins.

The CAD team generates the build plans. Their layouts provide the instruction for constructing the overall exhibit structure and custom fabricated elements, such as the reception desk shown here. The CAD layouts also provide direction for rigging, electrical, utilities, and construction of the actual exhibit on the show floor.

Fabrication and Construction

Now it is time for Acer’s master craftspeople to get to work.

The build moves through production and finishing in these expert hands, growing from a pile of boards into a cultivated brand environment. Acer’s comprehensive ten-step quality process ensures that each phase of the project is complete and flawless, before moving to the next one.

Once structure is complete, the in-house Acer graphic production team delivers the visual elements that communicate brand messaging. The final step in production is staging, where the exhibit (or certain key components) is set up in the Acer warehouse for client review and approval. This offers one last chance to make any small physical changes, update graphics or practice an attendee journey run-through.

Packing and Warehousing

During production, each and every piece of the exhibit is barcoded and tracked.

Now that the exhibit is ready to be packed up for transit to the show venue, the crates are packed with all contents logged and indicated on the outside of the crate.

Acer’s crating process ensures total traceability for every item. Our clients save countless thousands of dollars every year on labor costs, due to the efficiency of our inventory systems… installation teams never have to search for a specific part!

Show Ready

With everything delivered to the show venue, assembly crews get started under the watchful eye of an Acer Show Supervisor. Frequent status updates are provided, with photos documenting the construction and status along the way.

Electrical, audio/visual and experiential elements are tested and verified for correct functionality.

The show supervisor conducts a review and issues an installation report prior to releasing the installation crew.

It’s Showtime!

Upgrades and Improvements

ROCKWOOL can expect these properties to last three to five years, possibly more depending on a number of factors. In the second year, they decided to upgrade their hanging sign with a bolder, more dramatic look. The custom hanging sign we designed for ROCKWOOL went a long way to elevate their brand and enhance visibility from throughout the show floor.